أرسل لنا رسالة

Influence Of Jet Milling Process Parameters On Senegal

Milling

The Milling Process – Definitions Cutting speedv c Indicates the surface speed at which the cutting edge machines the workpiece Effective or true cutting speed v e Indicates the surface speed at the effective diameter DC apThis value is necessary for determining the true cutting data at the actual depth of cut a pThis is a particularly important value when using round insert cutters

Influence of Process Parameters on Abrasive Water Jet

AWJM is a nontraditional machining process in which material is removed by the erosion process where a very high pressure and very high velocity jet of abrasive particles and water slurry strikes on the work piece material Momber and Kovacevic in Principles of abrasive water jet machining Springer Milling blind pockets is majorly used in

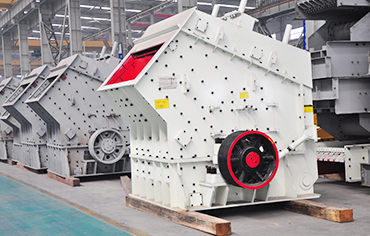

Milling Process Defects Equipment

Milling is the most common form of machining a material removal process which can create a variety of features on a part by cutting away the unwanted material The milling process requires a milling machine workpiece fixture and cutter The workpiece is a piece of preshaped material that is secured to the fixture which itself is attached to a platform inside the milling machine

Ioan Alexandru Popan PhD Universitatea Tehnica Cluj

The paper presents an experimental study on processing composite materials using abrasive water jet cutting AWJC process analysing one of the main process parameter standoff distance SOD

Spiral Jet Mills and HosokawaAlpine Jet Mills

Toner Fluidised Bed Opposed Jet Mill To the machine The TFG product line is a special variant of the fluidised bed opposed jet mill used for processing toner powder coatings and pigments

VLVRIDVHUHDP 0DFKLQLQJ3DUDPHWHUVIRUO

observed for different combination of process parameter such as laser power pulsing frequency cutting speed and assist gas pressure They have reported that GRSM is a effective technique in predicting the optimal setting of laser machining parameters Riveiro et al 6 have studied influence of

Milling formulas and definitions

Here you find a collection of good to have milling formulas and definitions that are used when it comes to the milling process milling cutters milling techniques and more Knowing how to calculate correct cutting speed feed per tooth or metal removal rate is crucial for good results in any milling operation

Process Capability and Average Roughness in Abrasive

Process Capability and Average Roughness in Abrasive Water Jet Cutting Process of Stainless Steel Process capability analysis is frequently employed to evaluate if a product or a process can meet the customer''s requirement "Influence of the CO2 laser cutting process parameters on the Quadratic Mean Roughness Rq of the low carbon steel

Waterjet Cutting Process Basics ESAB

Water Jet cutting uses an ultrigh pressure stream of water to carry an abrasive grit The abrasive does the cutting through a mechanical sawing action leaving a smooth precision cut surface Waterjet is the most versatile process because it is able to cut almost any type of material

SOFTWARE SOLUTION FOR ABRASIVE WATER JET

optimize it as a function of process parameters feed rate abrasive flow and water pressure The parameter which has the strongest influence on the water jet milling process is the feed rate V by increasing the feed rate the milling depth decreases

Numerical Study of Particle Motion in Jet Milling

Particles motions in a jet mill have great influence on the comminution process and energy consumption Therefore as a first step for a full simulation of the jetmill process it was decided to investigate the particle motion inside the jet mill by neglecting particleparticle interaction and

PDF Comparison of various milling technologies for

Although jet mill has several advantages but it is still an energy intensive process as only 25of the energy supplied is used to create new surfaces Mebtoul et al 4

Influence of Process Parameters and Electrode Shape

The objective of this paper is to study the influence of process parameters and electrode shape configuration on the machining characteristics such as surface quality material milling and drilling etc shows ineffectiveness in machining of advanced Water jet machining WJMAbrasive jet machining AJM Thermal Electrical discharge

Sensitivity Studies and Parameters Identification for

This work focuses on the identification of optimal model parameters related to Abrasive Waterjet Milling AWJM process The evenly movement as well as variations of the jet feed speed was taken into account and studied in terms of 3D time dependent AWJM model This gives us the opportunity to predict the shape of the milled trench surfaces

Modeling Cutting Forces for Five Axis Milling of

However desired machining productivity and precision can be obtained by physical modeling of machining processes via appropriate selection of process parameters In response to this gap in the industry this paper presents a cutting force model for 5axis ballend milling cutting force prediction

Influence of geometric design variables on the efficiency

Due to the fact that chromites with a high iron content are hard mill components like liner and grinding media wear faster than many mines which is a significant problem in chromite grinding This paper presents an experimental investigation of the influence of liner profile design and speed on chromite ball milling process

Influence of Fluidized Bed Jet Milling on Structural and

However a decrease in viscosity parameters of starch is found after jet milling and as classifier frequency increases The initial moisture content of starch shows a slight effect on the functional properties of the micronized starch The obtained results suggest that modified starch can be produced by fluidized bed jet milling

A dry separation technique for improving the quality of

The influence of the various process parameters on the yield of the cyclone products was insignificant Using the jet milling–fineness classification system we classified products by ash content sulfur content particle size and separation accuracy cascade change enabling the quality improvement and classification of coal products

Milling Process Defects Equipment

Milling is the most common form of machining a material removal process which can create a variety of features on a part by cutting away the unwanted material The milling process requires a milling machine workpiece fixture and cutter The workpiece is a piece of preshaped material that is secured to the fixture which itself is attached

Effect of process parameter on the kerf geometry in

Effect of process parameter on the kerf geometry in abrasive water jet milling kerf profile and the effect of process parameter on this profile are needed and traverse feed rate influence on

Effect of process parameter on the kerf geometry in

Apr 27 2010 · This research work introduces a model to predict the kerf profile in abrasive water jet slot milling in aluminium 7075T651 The experimentation allowed modelling the maximum cutting depth and the width at the half of maximum depth in terms of four process parameters pressure abrasive mass flow rate standoff distance and traverse feed rate

Cutting Speed and Cutting Velocity in Machining Their

During machining cutting velocity one of the important process parameters can be applied in four distinct ways as listed below Rotating workpiece For example lathe operations Rotating tool For example milling drilling and grinding operations Reciprocating workpiece

Experimental study of the influence of the process

Feb 07 2019 · Experimental study of the influence of the process parameters in the milling of Al6082T6 alloy M Jebaraj Department of Mechanical Engineering Experimental study of the influence of the process parameters in the milling of Al6082T6 alloy Machinability study of abrasive aqua jet parameters on hybrid metal matrix composite